Reducing Time in the Construction of High-Rise Buildings

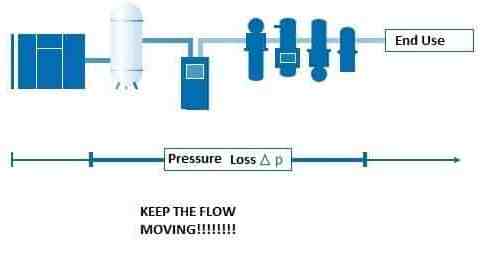

In the main, any change to one will inevitably affect at least one other. Cutting costs may result in an increase in the time taken, or a reduction in quality, while any improvement in quality will inevitably push up costs and/or time.

Of course, conversely, it is true that an increase in time taken may also result in a corresponding increase in costs as contractors spend longer on site requiring payment, and any overruns may result in fines or payment reductions. Delays may even potentially lead to a reduction in quality. However, the triangle of cause and effect can be broken by the application of improved systems, techniques, and technology. As such, keeping the time spent on a building project is of paramount importance. Here we hope to outline, in general terms, some of the ways in which it may be possible to cut the time taken on a job while not compromising on quality or increasing the overall costs.

5 ways to save time on high-rise building constructions

Much time can be saved by using effective organisation and systems, although many large construction firms already have effective systems in place and for these, the greatest savings may well come from the use of new technological solutions. As far as systems and organisation go, it all starts with good planning. It is often said that if you fail to plan you may as well plan to fail. Although this seems obvious it is the foundation of everything else. Making allowances for potential obstacles, and not underestimating costs and time are important to any project.

Correct selection of suppliers and contractors is also vital to any successful building project and it’s not just about who is the cheapest either. A professional approach can save a lot more time and money than picking the firm with the lowest quote.

Communication is the lynchpin of any successful project, both with the client and also with any suppliers and contractors. Keeping on top of every aspect of the job, knowing where you are and where you need to get to, keeping good control of deliveries and having the right people for each stage of the job will help keep costs down and still get the project finished on time.

However, if as it may be, this is a case of teaching grandmothers to suck eggs, we now come to two major technological solutions which could help with reducing time in the construction of high-rise buildings.

We are on the cusp of an era when more and more tasks, particularly repetitive ones, are carried out by robots, or other automated processes. Automation has, in the long run, probably the greatest potential for cost and time savings, particularly on hi-rise buildings where there is a particularly high proportion of repetition of tasks.

Then, of course, there is prefabrication of building components which on hi-rise buildings and other large construction projects has the potential to save a great deal of time. Both automation and prefabrication are key areas where significant savings can be made, particularly when you consider the ongoing skills shortage prevalent in the construction industry today.

What is Robotics in Construction?

While the idea of robotics in the building trade may seem like science-fiction there is already a significant place for automation in construction, and this will only grow as long as there is still a serious skills shortage in the UK. To date, the construction industry is one of the less automated areas of industry in the UK, but that, of course, means that the potential for major cost and time savings is all the greater. From bricklaying robots that can potentially work with perfect precision day and night, to 3D printers that can produce entire prefabricated sections of buildings, the future of construction, particularly of large projects, is likely to undergo one of the most profound changes in its entire history.

How Prefabrication Planning Can Save You Money

While the use of robotics in construction is still in its infancy in the UK, the use of prefabricated components is already fairly well established, with prefabrication having some part in over 90% of projects, although there are still many more opportunities for cost savings. There are, of course, some challenges to overcome before a successful deployment of prefabrication can be affected. Project managers will need to be reassured that last-minute changes to the overall design will not lead to prefabricated components needing to be modified or replaced causing delays.

So what are the benefits and the solutions to making prefabrication a success on projects? Assuming the planning and communication side of things is up to scratch and you have selected professional suppliers and contractors, the key benefits of prefabrication are in terms of cost and time savings as a result of requiring fewer people, particularly skilled workers, on site. Some of the larger prefabricated components require specialised delivery arrangements, however, this is more than compensated for the fact that there are far fewer deliveries of separate parts since these are all assembled off-site. There are also benefits in terms of reduced waste since components are already cut and formed to the correct size and any waste and recycling is dealt with during the manufacturing process and not on site. Prefabrication to precise measurements in advance of installation will also ensure there are no errors caused by working under pressure of time on a cramped building site.

Whether it is fixings and anchors, electrical containment, pipe supports, or larger components like walkways and stepovers; be it off-the-shelf or bespoke prefabrication, Fixmart can provide the right solution for your project. With delivery vehicles suited to the more complex demands of prefabricated components, and the ability to offer flexible and timed delivery slots, you can maximize time savings as well as keeping costs under control.