The Development Of 2022 China’S Rolling Mill Rolls Industry

Hot-rolled ribbed steel bars are one of the most important raw materials required by various industries in the national economy. With the continuous progress of technology, the production and quality of steel have significantly increased, and users’ requirements for material appearance quality have continuously increased. The appearance quality of hot-rolled ribbed steel bars has been highly valued by manufacturers and users. Therefore, quality control of steel is very important. So do you know the essential components in steel rolling production? I think that’s rolling mill rolls and cold rolling rolls.

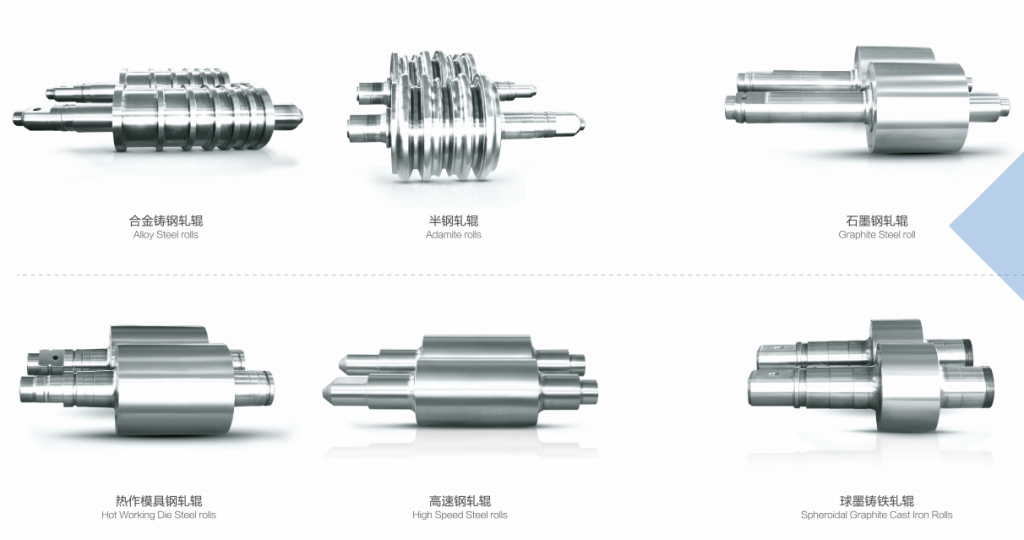

Rolling mill rolls is the main working component and tool on a rolling mill that causes continuous plastic deformation of the metal. The rolling roller mainly consists of three parts: the roller body, the roller neck, and the shaft head. The roll body is the middle part of the roll that actually participates in rolling metal. It has a smooth cylindrical or grooved surface. The roller neck is installed in the bearing and transmits the rolling force to the frame through the bearing seat and pressing device. The transmission end shaft head is connected to the gear seat through a connecting shaft, transmitting the rotational torque of the motor to the rolling roller. The rolls can be arranged in the form of two, three, four, or multiple rolls in the rolling mill frame.

Rolling mill rolls are one of the indispensable components in steel rolling production. With the improvement of steel quality requirements in recent years, the strengthening of the rolling process, and the increase of difficult-to-deform metals, high-grade steel, and stainless steel rolling, the requirements for the use conditions of rolls are becoming increasingly strict. Usually, the core of the rolls is required to have a certain degree of toughness to withstand torsion and bending stress, and a deep wear-resistant layer is required on the surface of the rolls, And it has high fatigue resistance.

China began mass production of cast hot rolled rolls in the 1930s, but there were very few varieties. In the late 1950s, China’s first professional roller mill was established in Xingtai, Hebei. In 1958, Anshan Iron and Steel Company made the first international trial production and used a large ductile iron roll for 1050 blooming. In the 1960s, we successfully manufactured cold-rolled work rolls and large forged steel rolls. In the late 1970s, Taiyuan Iron and Steel Company and Beijing Iron and Steel Research Institute jointly successfully trial-produced centrifugal cast iron rolls for coil rolling mills and hot strip rolling mills. Xingtai Metallurgical Machinery Roll Co., Ltd. successfully trial-produced semi-steel work rolls for hot strip rolling mills and work rolls for cold strip rolling mills. In the 1980s, China successively developed new varieties such as large forged steel support rollers, forged semi-steel and forged white cast iron rollers, powder tungsten carbide roller rings, and high chromium cast iron rollers. By the 1990s, China’s roller production had basically met domestic demand and had some exports, but the variety needed to be increased, and the quality needed to be improved.

Rolling mill rolls are mainly used for rolling steel, and various types of plates, bars, wires, profiles, and strips produced through rolling are widely used in real estate, railways, automobiles, household appliances, and other fields. From 2018 to 2022, the demand for rolls in China increased from 1.137 million tons to 1.24 million tons.

China is a major manufacturing country with a huge demand for steel in downstream industries such as automobiles, shipbuilding, and home appliances, which in turn drives the development of the rolling industry. Currently, China is the world’s largest rolling production country, with a production of 1.27 million tons and a demand of 1.24 million tons in 2022. Overall, benefiting from the development of downstream industries, the supply and demand of China’s rolling industry are stable, and with changes in downstream demand, technology is constantly updated and iterated. At present, micro-casting forging piercing mill rolls and high-speed steel rolls have become research directions in the industry.