An Article About Woodworking Carbide Reversible Knives – UKO Blog

As you know, the traditional flat knife such as alloy knife, shaping knife has the following problems:

- Burning of the cutting edge: when the cutting edge is worn or the feed is temporarily stopped, the cutting heat will produce burn marks on the cutting surface.

- Tool passivation and stability: The increase in tool temperature increases the temperature of the cutting edge and increases the passivation speed of the tool; and the uneven temperature distribution of the tool body will cause the tool to lose its original stability.

- Cutting that is prone to tearing: the flat blade has a large force area during cutting, and it is easy to form cutting deformation. There are also relatively large damage marks on the wood, and the cutting surface cannot meet the requirements of flat and smooth.

- Difficult chip removal: The wood chips after cutting by the flat knife are large. In the central integrated system, the oversized wood chips cannot be discharged in real-time, resulting in the processed wood chips affecting the processing quality.

- Reduction of alloy hardness: Under the operation of high-temperature welding flat blades, it is easy to reduce the alloy hardness and greatly reduce the service life of the tool.

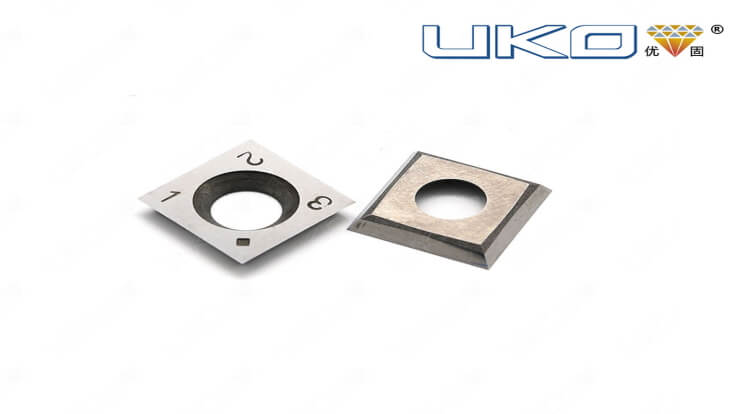

The design principle of woodworking carbide reversible knives improves the disadvantages of the above flat cutters and increases the convenience.

- Spiral blade surface: Improve the bad situation of blade burn and the tear-type blade mark caused by a flat knife.

- Fast heat dissipation: some knife models are made of aluminum alloy knife body, which indicates the stability and service life of the knife.

- The wood chips are extremely small: the wood chips formed by spiral cutting per unit time are extremely small, and it is easy to discharge the wood chips away from the wood surface in the central integrated system.

- Less noise: the noise value generated when the surface of the wood and the flat knife touch the surface of the wood at the same time is relatively low at about 70%.

Through the article introduction and explanation, I think you now are clear about the blade for woodworking. I hope this file will be useful to you. By the way, we also have its relevant products like spiral cutter head and DW735 as well.