Industrial Mufflers

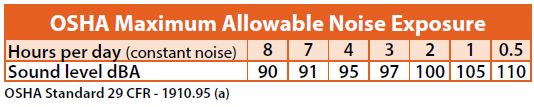

Many manufacturing plants have a strong focus on safety for their workers. One major safety concern that is overlooked is noise. The Occupational Safety and Health Administration has a directive, 29 CFR 1910.95a, that defines noise exposure levels over time. For an eight-hour day, the maximum noise level is 90 dBA. Hearing loss is irreversible, but it can be prevented. The CDC, Center for Disease Control, and NIOSH, National Institute for Occupational Safety and Health, report that “approximately 18% of all manufacturing workers have hearing difficulty”1.

EXAIR manufactures intelligent compressed air® products to reduce noise levels in the work environment with our Super Air Nozzles, Super Air Knives, and Safety Air Guns for blow-off applications. But there is another culprit that can be heard; discharge exhaust. In this blog, I will cover the different types of mufflers that we offer to help reduce these sound levels.

Reclassifying Mufflers are designed to have two functions. They can cut noise levels by 35 dB and remove oil mist from the exhaust air. Cylinders and valves that exhaust pressurized air may have oil in the line to keep the seals from sticking. When exhausted, it can create a fine mist, which is dangerous for operators. Reclassifying mufflers can reduce loud noise while also collecting any contaminants in the exhaust air.

Sintered Bronze Mufflers are simple in design, cost-effective, and easy to install. They have minimal back pressure to not restrict the operations of the pneumatic device. They come in sizes from #10-32 thread to 1-1/2” NPT. For a quick and simple way to reduce noise, the Sintered Bronze Mufflers are in stock for fast delivery.

Straight-Through Mufflers offer a way to reduce noise levels without worrying about clogging. They have an aluminum shell lined with sound-absorbing foam, and they can reduce the noise level by 20 dB. EXAIR offers them with ports of ¼” NPT, 3/8” NPT, and ¾” NPT. One side has a female thread, while the opposite side will have a male thread. This can allow you to connect other items like hose kits to reduce noise.

In harsh environments, Heavy Duty Mufflers are used. They have an outer aluminum shell with an internal stainless-steel screen. They protect components like valves and cylinders from contamination entering the part. And, the Heavy Duty Muffler can keep contaminants like rust from being ejected at high speed into the work area. They have a typical noise reduction of 14 dB.

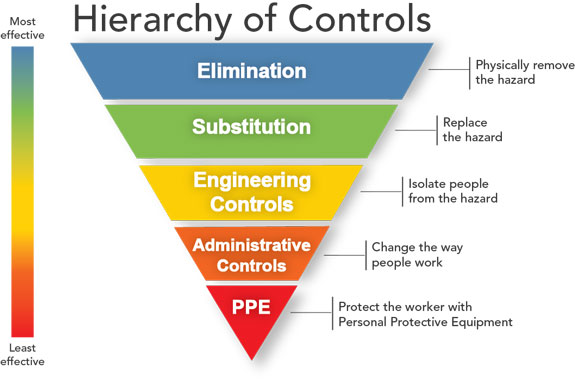

Here is a test for you. If you go and stand in your plant, you can probably hear loud noises coming from your pneumatic system. EXAIR has engineered products to solve most of them. In the Hierarchy of Controls from NIOSH, Personal Protection Equipment, or PPE, is the least effective. A better control from this chart would be to isolate your operators from the hazard with an engineered product. EXAIR can offer these solutions for many of your blow-off and pneumatic discharge applications. If you wish to discuss in further details about the safety improvements that EXAIR can provide, you can contact an Application Engineer. We will be happy to help.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb

Note 1: https://www.cdc.gov/niosh/topics/ohl/manufacturing.html