Additional Details About Steel Angle Bracke

Certainly! Here are some additional details about steel angle brackets:

Types of Steel:

Steel angle brackets can be made from different types of steel, including carbon steel and stainless steel. Carbon steel brackets are commonly used in general construction and woodworking applications due to their strength and affordability. Stainless steel brackets are preferred in environments where corrosion resistance is crucial, such as outdoor or high-moisture settings.

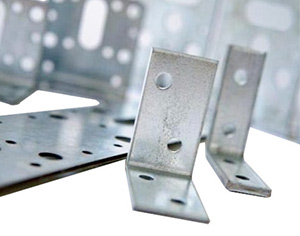

Surface Finishes:

Steel angle brackets may have different surface finishes to enhance their appearance and provide additional protection against corrosion. Common finishes include galvanized coatings, which involve applying a layer of zinc to the surface of the bracket, and powder coating, where a durable powder paint is electrostatically applied and cured onto the bracket.

Load-Bearing Capacity:

Steel angle brackets are designed to withstand significant loads and provide robust support. The load-bearing capacity of a bracket depends on factors such as its size, thickness, material, and configuration. It is essential to choose a bracket that matches the specific load requirements of your project to ensure structural integrity and safety.

Hole Patterns:

Steel angle brackets often feature a pattern of holes along both arms to allow for flexible attachment options. These holes provide multiple points of connection, enabling you to secure the bracket to surfaces using screws, bolts, or nails. The hole patterns can vary, with commonly used options including round holes, slotted holes, or a combination of both.

Applications:

Steel angle brackets find applications in various industries and projects. They are commonly used in construction for connecting and reinforcing structural elements, such as beams, columns, or trusses. In woodworking, they provide support for shelves, cabinets, or furniture joints. Steel angle brackets are also employed in DIY projects, industrial settings, and hardware installations.

Customization:

Depending on the manufacturer or supplier, steel angle brackets may offer options for customization. This can include variations in size, hole patterns, or additional features tailored to specific project requirements. Customization allows for versatility and ensures that brackets meet the exact needs of your application.

When using steel angle brackets, it is important to follow proper installation techniques and guidelines provided by the manufacturer. Ensure that brackets are securely fastened to the surfaces and that appropriate hardware is used to achieve the desired level of strength and stability.

It is always advisable to consult professionals or experts in construction or engineering if you have specific questions or concerns regarding the selection, installation, or load-bearing capabilities of steel angle brackets for your project.