Implications of storing compressed air

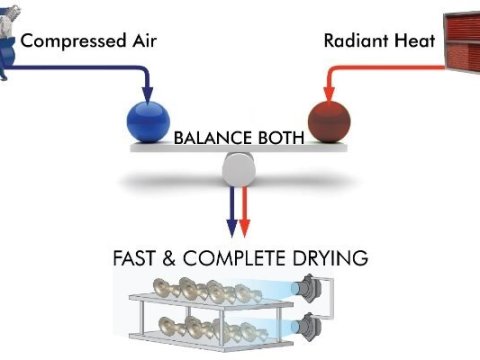

When compressed air is produced, it is first stored and then utilized from storage as it is needed. This has implications for actual energy use and cost.

Storage in a compressed air system allows users to supplement energy usage during high-demand periods, enhances air quality, and maintains system stability.

Compressed air is drawn from storage through some pressure regulation and is provided in a specific pressure range. When the pressure in the stored tank reaches the upper level, the compressor stops. When it drops to the lower level, the compressor turns on to build the pressure up to the upper limit.

The overall consumption of compressed air in the manufacturing facility must be less than that produced by the air compressor in the same period.

Compressed air’s implicit advantage is that the energy is stored, and waste is minimized as it can be used only when needed. The storage capacity needs to be large enough to handle the capacity needed to prevent the pressure in the systems from dropping.

This video outlines calculating the amount of compressed air stored between the upper and lower pressure setting on the storage volume.

This can be an advantage when there are peak times when the air is needed, so you have enough to handle that demand but do not have to expend extra energy to produce the air needed.

Air quality is enhanced with storage as it allows moisture in the compressed air to condense out of the air as it cools within the storage tank and is drained off, not getting into the delivery system.

The storage tank also absorbs the pulse of the compressor going on and off when filling the tank by dampening the effect and keeping the compressed air delivery system stable.

Compressed air storage is very effective, especially in blow-off applications with on-off control. For example, if a blow-off static requires a blast of air for five seconds and then off for five seconds and uses 50 SCFM of compressed air, the actual consumption from the storage is 25 SCFM on average. This helps determine the actual size and availability of energy required and used.

Video : https://youtu.be/cGZnSpvvyig