Air Amplifier Jet or Knife

What are Air Amplifiers, Jets, and Knives?

Air Amplifier

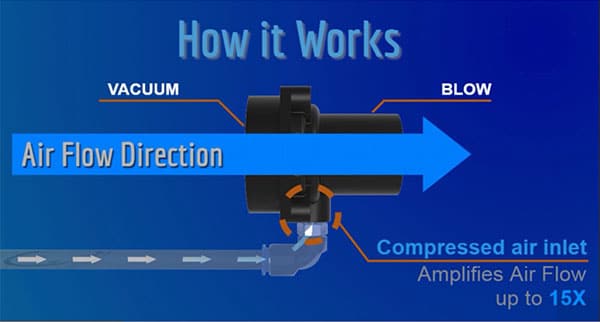

There are two types of Air Amplifiers – Air Pressure Amplifiers and Air Volume Amplifiers. This article talks about volume amplifiers, which harness the energy from a small parcel of compressed air to produce high velocity and volume, low pressure air flow as the output. It can amplify the volume up to 17 times the air consumed.

The volume amplifier uses an aerodynamic effect called “the Coandă effect”. One example of this effect is seen on the Coandă angles on airplane’s wing that can cause the airplane to lift. In an airflow amplifier, the force is directed outward to cool or dry a surface. Pressure normally lost as noise and is converted into amplified and high velocity laminar flow.

Compressed air stream flows through an air inlet, clinging to the “Coandă” profile inside. The compressed air is throttled through a small ring nozzle at high velocity and guided towards the outlet. This results in a low-pressure area at the center, inducing a high volume of surrounding air flow to the airstream. Airflow is further amplified downstream by entraining additional air from the surroundings at the exit. This adds further volume and flow to the primary airstream via a similar method. The combined flow of primary and surrounding air exhausts from the Air Amplifier is a high volume, high velocity flow.

The jets of air in the amplifiers create a high velocity flow across the entire cross-sectional area, which pulls in large amounts surrounding air, resulting in the amplified outlet flow.

Note: Air Amplification Ratio is the ratio of the air flow in standard cubic feet/minute (SCFM) or standard liters per minute (SLPM) at the exit point divided by compressed air consumption with the same unit. This ratio can vary with inlet pressure and temperature as well as the density of the inlet air, so the figure provided is a weighted average. The ratio may be reduced if any back pressure is put on the amplifier exit or suction end by attaching a hose, pipe or tubing

There is a balanced between amplified air flow and air velocity. Any air amplification ratio higher than 17 will slow the velocity so much that the blow off force becomes ineffective and the cooling effect lost.

NOTE: It is recommended to regulate the compressed air supply so the very least amount of air necessary is used. Install a solenoid valve on the compressed air supply side to turn the air off when the air amplifier is not in service.

Air Jet

Air Jets are either annular like Air Amplifiers or in a flat design (air edger). Due to their size and “Coanda profile”, annular Air Jets provide a greater concentrated force using amplified air. This makes them ideal for applications like part ejection. Nex Flow Flat air jets or Flat Jet Nozzles are a compressed air operated chamber of shorter length than an air knife with a higher force and flow design. The internal chamber and outside shape are designed to minimize pressure drop and convert this into flow and force.

Flat Air Jet Nozzle (Air Edger®) is used when a much stronger forced air is required than an air knife can provide. The flat jet nozzle can be mounted on manifolds of different lengths (holding 2, 4, or 6 units typically and more). Like an air knife – shims can be added to produce higher force. Due to the chamber design that is quite different from an air knife – a greater range of shims can be added to the flat nozzle allowing it to produce much higher air force than an air knife is able to provide.

The Air Edger® Flat Jet is available with various size “gaps” all set with a flat stainless steel shim. Three standard shim sizes are available – .004” (.10 mm), .008” (.2mm) and .020” (.51 mm). Shims can be “stacked” for a larger gap and greater force up to a maximum gap of .024” (61 mm).

Air Knife

An air knife is positive pressurized air chamber that contains a series of holes or continuous slot through which a predetermined air volume and velocity exits. The air is blasted through the air chamber using an air compressor or industrial blower. The air knife is typically made from either aluminum or stainless steel of various lengths but can be made of other materials as well.

Note: Electrical currents from anti-static bars can also be injected into the air knife air stream to neutralize the static electricity charge on some surfaces.

Things to consider when choosing an air knife includes:

- Force required

- Material: typically aluminum, stainless steel, and special plastics

- Required Length or distance from the compressed air source to the target.

- Installation Cost

- Noise

- Air Consumption

Applications of Amplifier, Jets and Knives

Air Amplifier

There are many different applications for air amplifiers to completely list – but main applications include blow off, cooling, and ventilation:

- Blow off:

- Purging tanks

- Used in ventilation of fumes, smoke, lightweight materials from automobiles, welding, truck repair, plating or holding tank or other confined spaces.

- Circulate and blow off air

- Cool hot parts: Cooling dies and molds

- Dry wet parts

- Clean machined parts:

- Vacuum device to clean machined parts and confined places: dust collection, remove metal chips and scrap, collect and move dust (grain operations)

- Clean a conveyor belt or web

- Convey:

- Used to convey small parts, pellets, powders, and dust.

- Exhaust tank fumes; Used to remove fumes quickly and efficiently for venting applications. The fumes can be ducted away, up to 50 feet (15.24 m), and the amount of suction and flow is easily controlled.

- Moves air 12 to 20-fold in duct applications and up to 60 times in areas with no ducts.

- Component removal, valve gates, and automated equipment for ejection molding systems

- Distribute heat in molds/ovens

- Sort objects by weight

- Used as tools in production lines, wood working, aerospace, construction, dentistry, heath care and hospitals

- Used in assembly, chemical processing, robotic cells, and chemical processing

- Increasing existing plant air pressures

- Used in medical, food, and pharmaceutical installations

- Used in Pneumonic cylinders: Enhances efficiency of pneumonic tools and machinery

- Bottle molding applications

- To enhance the “WOW!” factor of amusement rides in certain thrill rides; such as roller coasters

- Coat a surface with atomized mist of liquid

- Activating adhesives and heating-shrinking: High air amplification puts much more airflow through the heater coils than would be possible with an ordinary fan or blower. The hot airstream can be felt over 10′ (3m) away!

Based on Type, Size, and Material:

| Type | Outlet Diameter | Application |

| Standard (Fixed)1 | ¾” (19 mm) | High temperature /corrosive (up to temperature of 700 F (371 C) |

| 1-1/4” (32 mm) |

Cooling

Moving hot air for uniform heating in ovens or furnaces Exhaust Circulate air, move smoke, fumes, and light material Clean and dry parts |

|

| 2” (51 mm) | ||

| 4” (102 mm) | Circulate air, move smoke, fumes, and light material

Clean and dry parts Venting or cooling |

|

| 8” (203 mm) | Circulate air, move smoke, fumes, and light material

Venting or cooling |

|

| Adjustable2 | ¾” (19 mm) | High temperature /corrosive (up to temperature of 700 F (371 C) |

| 1 1/4” (32 mm) | Cooling

Moving hot air for uniform heating in ovens or furnaces Exhaust Circulate air, move smoke, fumes, and light material Clean and dry parts |

|

| 2” (51 mm) | ||

| 4” (102 mm) | Circulate air, move smoke, fumes, and light material

Clean and dry parts Venting or cooling |

- Available 0.002 and 0.003” shims can be added

- Gap setting from 0.001” to 0.004” to control the output flow and force required.

| Material | Application |

| Plastic | Cooling

Moving hot air for uniform heating in ovens or furnaces Exhaust Circulate air, move smoke, fumes, and light material Clean and dry parts |

| Aluminum | High temperature/corrosive |

| Stainless steel | High temperature/corrosive (up to temperature of 700 F (371 C)

Medical, food, and pharma installations Blow off, cooling, or venting |

Special plastic versions are used to cool materials in an electrical power grid where metals can not be used. Alternative materials can be machined to be used as an air amplifier unit in corrosive environments where stainless steel is not sufficient.

Nex Flow manufactures special Air Amplifiers to your specification including special flanged mounting style or with a PTFE plug to avoid sticky material build up.

Benefits to Using Air Amplifiers: For air amplifiers, the outlet flow remains balanced and minimizes wind shear, sound levels are typically three times lower than other types of air movers. Both the vacuum and discharge end of the Air amplifier can be ducted, making them ideal for drawing fresh air from another location or moving smoke and fumes away. They are ideal for increasing existing plant air volume for blowing or cooling and for venting.

- Compact, lightweight, portable

- No electricity

- No moving parts – no maintenance

- Ends are easily ducted

- Instant on/off

- Longer life in difficult environments than competitive models.

- Lower compressed air consumption than ejectors and venturi.

- Maintenance free with output easily controlled, safe to use.

Air Jet

Flat jet air nozzles are used for a concentrated and targeted application of air and other gases. They are used to provide a powerful stream of high velocity laminar flow and high force for blow off and cooling applications where air knives are not sufficient.

Annular Air Jets entrain large volumes of surrounding air through the Jet (like Air Amplifiers) and are more efficient flow amplifiers than Air Nozzles. They cover a larger blow off target than a Nozzle and are ideal for part ejection. An air nozzle provides a point force, while the Air Jet acts more like a “hand” and covers a larger area in blow off coverage. This can be an advantage in part ejection where two nozzles are normally required to “direct” the ejected part while only one jet is needed. This can dramatically reduce energy required as well as have a lower footprint on the machine.

Applications of an air jet:

- Part cleaning

- Chip removal

- Part drying

- Part ejection

- Air assist

- For moving heavier material that requires extra force to move.

Benefits to using an Air Jet: Air consumption and noise levels are minimized with its special design and configuration while providing a strong blow off force.

- Reduced compressed air cost

- 10 dBA average noise reduction

- Conserve compressed air

- Compact

- Improved safety

- Meets OSHA noise level requirements

- Improved production

Air Knife

An air knife is used to create an air curtain to clean, dry, or cool a surface of a product without mechanical contact. In most cases, the air knives are stationary while the products that are cleaned or cooled are traveling on conveyors. In other manufacturing applications, the air knife moves or rotates over the surface of the stationary product. In rare circumstances, an air knife can be used to cut products. One such example in the food industry is by using an air knife to cut into cake frosting.

The following is a comprehensive list of air knife applications using compressed air:

- An air knife is used to blow off a curved or flat surface of unwanted liquid (such as water), grime, airborne debris, dirt, or dust from surfaces or objects using a high-intensity, uniform sheet of amplified airflow.

- Air knives are a good cooling tool.

- They are also used to control the thickness of liquids

- Used in food, pharmaceutical, packaging, automotive, mining, heavy industries (steel and aluminum), and circuit board manufacturing, and printing

- Used the first step in recycling to separate lighter particles from other components.

- Used in post manufacturing of parts for drying, conveyor component cleaning, and to draw in waste fumes or exhaust.

- Create an invisible air barrier to separate heated or cooled environments from one another in industrial applications such as continuous metal heat treating ovens, cold process or storage areas in food processing or dust containment for the entrance to clean rooms.

- Removal of excess oils, liquids, and dust from flat and curved surfaces

- Part Drying after wash

- Conveyor cleaning

- Component or Parts Cooling

- Drying or Cleaning of Moving Webs

- Environmental Separation (air barriers)

- Blow off in pre-paint systems

- Bag opening in filling applications

- Scrap Removal in converting operations

Benefits to Using compressed air – air knife: Compressed air operated air knives are more compact in design, easier to control, and far less noisy than blower operated units.

- Quiet – 69 dBA for most applications

- Uniform airflow across entire length

- Minimal Air Consumption

- High Force/Air Consumption Ratio

- Variable force and flow

- No moving parts – maintenance free

- Easy mounting

- Compact, rugged, easy to install

- Stainless steel screws in all models

- Standard Units 30:1 air amplification

- X-Stream Units 40:1 air amplification

- X-Steam Units can do the same job as competition at lower pressures

- Materials Anodized Aluminum, Hard Anodized Aluminum, 303/304 stainless steel and 316L stainless steel

- Stainless Steel shim

- Special Lengths Available

Blower operated systems are advertised as being more energy efficient but that is not always the case. In intermittent blowing and lower pressure applications, compressed air knives can be as energy efficient as blower operated systems.

Compressed air operated air knives have smaller/more compact dimensions, more rugged, quieter, and do not have the costly maintenance compared with blowers, making compressed air operated systems the smart choice especially when space is a premium. A compressed air operated air knife provides significantly more force than a typical blower.

Air knives are ideal for liquid and dust blow off. Air knives provide clean, heated air; low operating noise (even without sound enclosures); and easy installation and operation.

Drawbacks to Using Compressed air – Air knife: Not good for heavier material that needs to be removed. In this case, choose an air jet.

Conclusion

Compressed air operated Air Amplifiers, Jets, and Knives are effective tools for your manufacturing environment. It is critical to know the requirements of your application to choose the correct product. Experts at Nex Flow are happy to assist you in choosing your compressed air solution for your manufacturing application.