Bolt Heads and Threads

How are the bolt heads and threads processed?

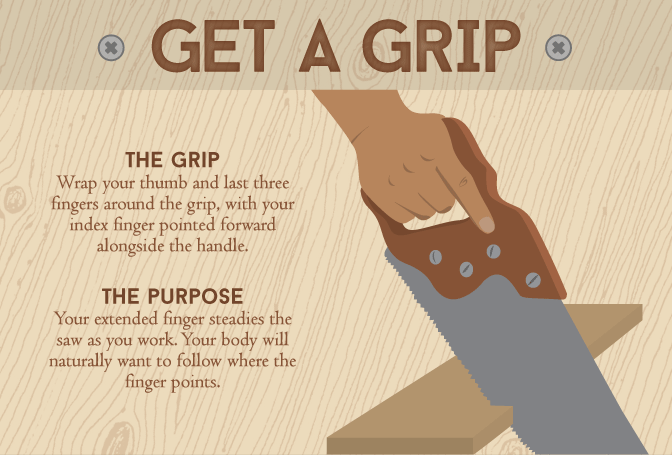

The forming of bolt head adopts cold heading plastic processing. Compared with cutting processing, the metal fibers are continuous along the shape of the product without cutting in the middle, which improves the strength of the product, especially the mechanical properties. Cold upsetting process includes cutting and forming, single-station click, double-click cold upsetting and multi-station automatic cold upsetting. Instead, the automatic cold heading machine itself is used to cut and upset the rough (if necessary) blanks from bars and wire rods. Before extruding the cavity, the blank must be shaping. Through shaping, the blank which meets the technological requirements can be obtained. Before upsetting, diameter reduction and forward extrusion, the blank does not need to be shaping. After the blank is cut off, it is sent to upsetting and shaping station. This position can improve the quality of the blank, reduce the forming force of the next position by 15-17%, and prolong the life of the die. The bolt can be manufactured by reducing the diameter several times.

Bolt heads and threads are usually processed by cold, so that the thread blanks in a certain diameter range can be formed by rubbing (rolling) the screw plate (die), and by the pressure of the screw plate (rolling die). The plastic streamline of the threaded part can be obtained without cutting off, the strength is increased, the precision is high and the quality is uniform, so it is widely used. In order to produce the thread outer diameter of the final product, the required thread blank diameter is different, because it is limited by the thread accuracy, material coating and other factors. Rolling (rubbing) threading refers to the process of forming threaded teeth by plastic deformation. It uses a rolling die with the same thread pitch and conodont as the processed thread to extrude the cylindrical screw blank and rotate the screw blank at the same time. Finally, the conodont on the rolling die is transferred to the screw blank to form the thread. The common point of rolling (rubbing) thread pressing is that the rolling speed does not need to be too much, if too much, the efficiency is low, and the surface of thread teeth is prone to separate or screw-up phenomenon. On the contrary, if the rotation is too small, the thread diameter is easy to lose circle, and the pressure increases abnormally at the initial rolling stage, which shortens the life of the die. Common defects of rolling threads: surface cracks or scratches on the part of threads; screw-ups; partial roundness of threads. If these defects occur in large numbers, they will be found in the processing stage. If the number of defects occurs less, the production process will not notice these defects will flow to users, causing trouble. Therefore, the key problems of processing conditions should be summarized, and these key factors should be controlled in the production process.

Stainless Steel Hexagon Bolt

Stainless Steel Hexagon Bolt, DIN 931 Hex Bolt, din933 zinc-plating hex head bolts on sale, Zinc-plating m38 nut and bolt for industry, nut and bolt m13 m48 anchor bolt coupler ss 304 customized size din 931 low head hex bolt fastener Stainless Steel Hexagon Bolt Standard DIN GB ISO JIS BA ANSI Size M2-M52 Material […]