Why do we passivate carbide cutting tools? UKO Blog

Many friend have such a question, the CNC tool used in machining center is not the faster the better, why passivation treatment? In fact, tool passivation is not a literal meaning, but a way to improve tool life. Through leveling, polishing, deburring and other processes to improve the quality of cutting tools. This is actually a normal process after finishing grinding and before coating.

What is tool passivation?

Through deburring, leveling and polishing, the quality and service life of the tool can be improved. The name of a process after finishing grinding and before coating is not unified at home and abroad, such as “edge passivation”, “edge strengthening”, “edge honing”, “edge preparation” or “Er (edge radiating) treatment”.

Why do tool passivation?

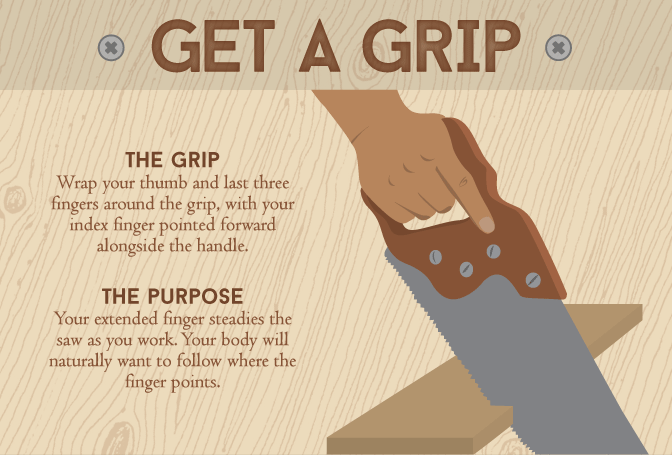

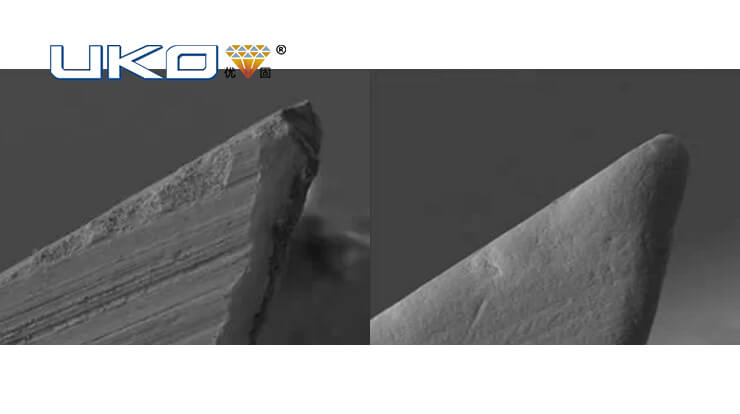

There are different micro notches (i.e. micro chipping and saw edge) on the tool edge grinded by ordinary grinding wheel or diamond grinding wheel. In the cutting process, the micro notch of the tool edge is easy to expand, which accelerates the tool wear and damage.

Modern high-speed cutting and automatic machine tools put forward higher requirements for the performance and stability of cutting tools, especially the coated tools must be passivated before coating to ensure the firmness and service life of the coating. The purpose of edge passivation technology is to solve the micro notch defect of the tool edge after grinding, reduce or eliminate the edge value, and achieve the purpose of smooth, sharp and durable.

Main effect of tool passivation

Edge rounding: remove the edge burr to achieve accurate and consistent rounding.

The edge burr causes tool wear, and the surface of the workpiece will become rough. After passivation, the edge becomes very smooth, which greatly reduces the chipping and improves the surface finish of the workpiece.

Polishing treatment of row cutting groove

The tool groove is polished evenly to improve the surface quality and row cutting performance.

The smoother the groove surface is, the better chip removal will be, and higher cutting speed can be achieved. At the same time, with the improvement of the surface quality, the risk of tool and material bite is reduced. Cutting force can be reduced by 40%.

Polishing of coating

Remove the protruding droplets produced by the tool coating, improve the surface finish and increase the adsorption of lubricating oil.

The coated tool surface will produce some tiny protruding droplets, which can improve the surface roughness, make the tool easy to produce large friction heat in the cutting process and reduce the cutting speed. After passivation and polishing, the droplets are removed and many small holes are left. More cutting fluid can be absorbed during machining, which greatly reduces the heat generated during cutting and greatly improves the cutting speed.

UKO can customize carbide cutting tool products with customer needs, or provide customized optimization scheme for customers according to customer test report to meet the diversified needs of customers.