Progressive cavity pumps are essential components in various industries, providing efficient and reliable fluid transfer solutions. Their unique design allows for the handling of viscous fluids, slurries, and other challenging materials. This versatility makes progressive cavity pump manufacturers valuable partners for numerous sectors. In this article, we will explore the various industries and applications that can benefit from these manufacturers.

Understanding Progressive Cavity Pumps

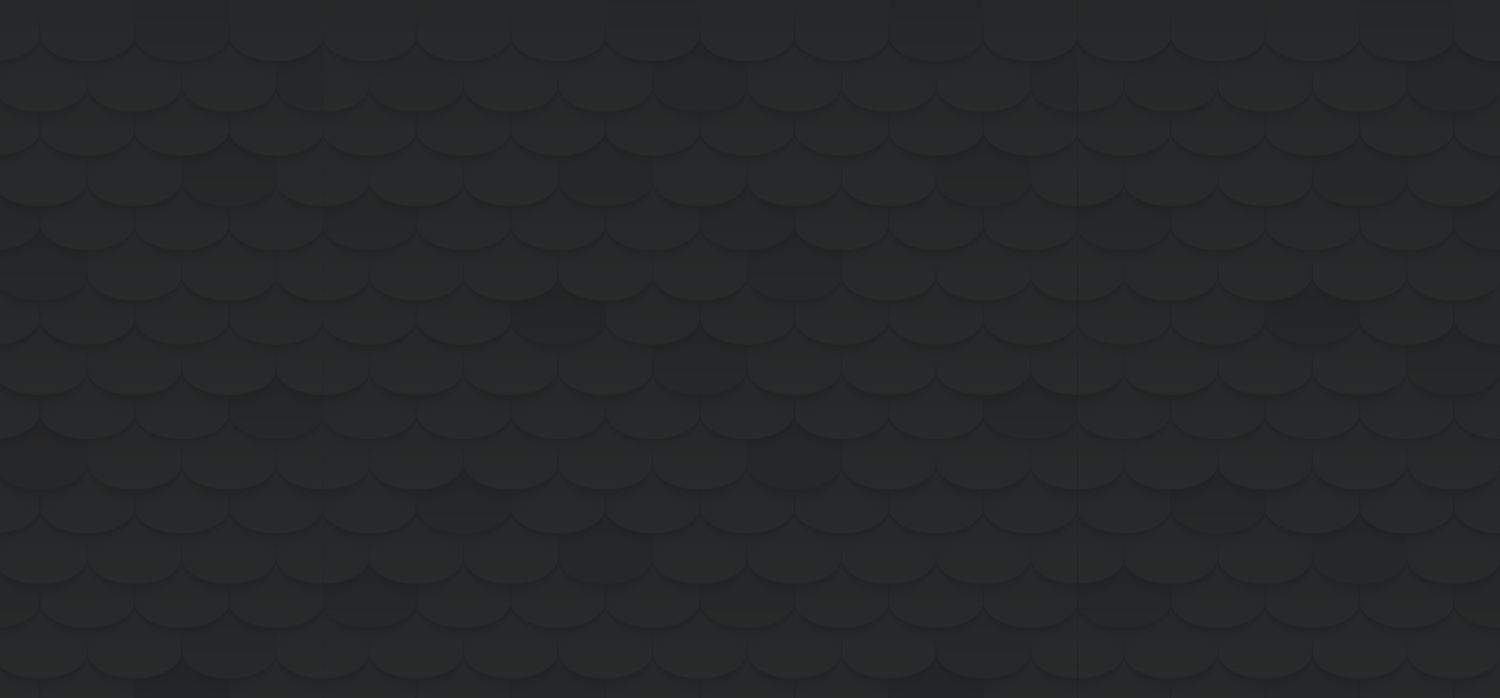

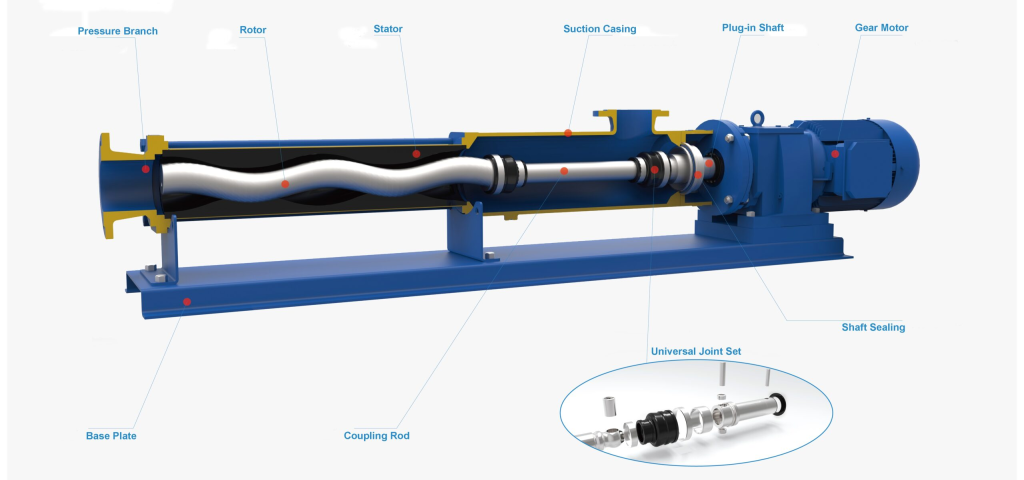

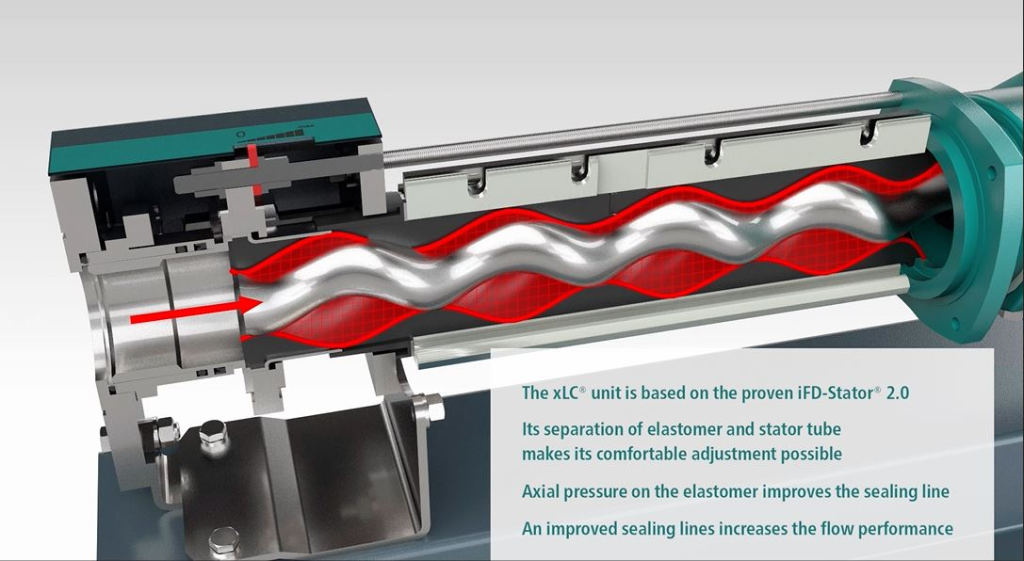

Before diving into who can benefit from a progressive cavity pump manufacturer, it’s important to understand what these pumps are and how they work. A progressive cavity pump consists of a helical rotor rotating within a stator. This design creates a series of sealed cavities that move fluid from the inlet to the outlet. The design allows for smooth, continuous flow, making it ideal for applications involving thick or shear-sensitive fluids.

Industries That Benefit from Progressive Cavity Pump Manufacturers

1. Oil and Gas Industry

The oil and gas industry often deals with high-viscosity fluids, including crude oil and drilling mud. Progressive cavity pumps are invaluable in this sector for:

- Fluid Transfer: Efficiently moving crude oil and other viscous fluids.

- Enhanced Oil Recovery: Assisting in the extraction process by handling complex mixtures.

- Waste Management: Pumping out drilling fluids and wastewater with ease.

2. Food and Beverage Industry

In the food and beverage industry, maintaining product integrity is crucial. Progressive cavity pumps offer benefits such as:

- Gentle Handling: Minimizing shear stress on sensitive products like dairy and sauces.

- Hygienic Design: Ensuring compliance with food safety regulations and standards.

- Versatility: Effectively transferring various food products, from thick pastes to liquids.

3. Wastewater Treatment

Progressive cavity pumps are widely used in wastewater treatment facilities due to their ability to handle solids and viscous materials. Key benefits include:

- Reliable Performance: Maintaining consistent flow rates despite varying conditions.

- Durability: Able to withstand harsh environments and corrosive materials.

- Energy Efficiency: Reducing operational costs by providing efficient fluid transfer.

4. Chemical Processing

The chemical industry often requires precise handling of various substances, including corrosive and viscous materials. Benefits in this sector include:

- Chemical Compatibility: Materials of construction can be tailored to resist corrosion and abrasion.

- Controlled Flow Rates: Ensuring accurate dosing and mixing of chemicals.

- Adaptability: Suitable for a wide range of chemical processes, from manufacturing to waste disposal.

5. Mining and Mineral Processing

In mining operations, progressive cavity pumps can significantly improve efficiency in transporting slurry and other materials. Advantages include:

- Handling Abrasive Materials: Designed to pump slurries containing solid particles without significant wear.

- High Viscosity Capability: Effectively managing thick mixtures common in mineral processing.

- Reduced Maintenance: Lower wear and tear lead to fewer maintenance interventions.

Key Considerations When Choosing a Progressive Cavity Pump Manufacturer

When selecting a progressive cavity pump manufacturer, there are several factors to consider:

- Experience and Expertise: Look for manufacturers with a proven track record in your industry.

- Customization Options: Ensure they can tailor pumps to meet your specific needs.

- Quality Assurance: Check for certifications and quality control processes.

- Customer Support: Reliable post-sale service can make a significant difference in performance.

- Innovation: A manufacturer that invests in research and development is more likely to offer advanced solutions.

Conclusion

Progressive cavity pump manufacturers serve a wide range of industries, providing tailored solutions to meet diverse fluid handling needs. From oil and gas to food processing, their pumps deliver efficiency, reliability, and performance. By understanding the specific benefits that these manufacturers offer, businesses can make informed decisions that enhance their operations. Investing in a reputable progressive cavity pump manufacturer can lead to significant improvements in productivity and efficiency, ultimately driving success in various applications.