What are some common applications for carbide inserts?

As you know, carbide inserts are indispensable in numerous industries due to their exceptional durability and versatility. Let’s delve into their applications, advantages, and identification methods.

First, what is carbide inserts?

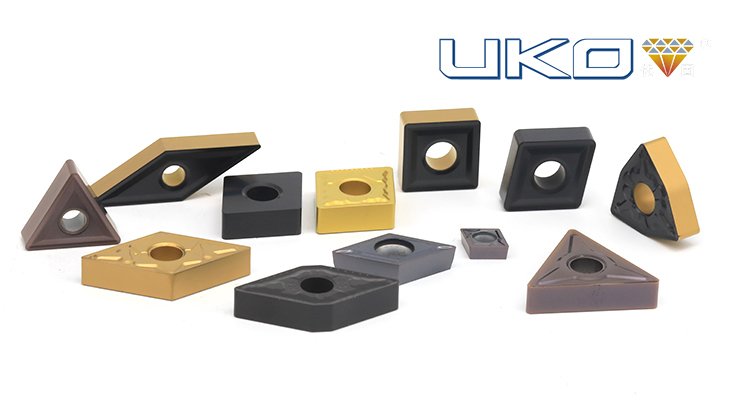

Carbide inserts are cutting tools made from hard tungsten carbide material. These inserts are specifically designed to be easily replaceable within cutting tools like milling cutters, drills, and turning tools.

Secondly, what is tungsten carbide inserts used for?

Tungsten carbide tools are widely serving in various industries for cutting and shaping. They can do machining hard materials like metals, wood, plastics, and composites. They find applications in metalworking, woodworking, mining, manufacturing, and other fields requiring precision cutting.

Thirdly, what is the advantage of carbide insert?

Compared to traditional high-speed steel tools, the advantages of carbide tools include exceptional hardness, wear resistance and high heat resistance . In addition, carbide milling and turning inserts retain their cutting edges for longer periods, resulting in increased tool life and improved machining efficiency.

Cemented carbide insert offers several advantages:

- Durability: They withstand high temperatures and abrasion, ensuring prolonged tool life.

- Precision: Carbide inserts maintain sharp edges, ensuring precise cuts and finishes.

- Versatility: They adapt to diverse machining tasks across multiple industries.

Fourth, how do I know if my insert is carbide?

To determine if an insert is a ture of carbide, check its composition. Carbide inserts typically feature a metallic surface with a dull grey color, and may have markings or engravings indicating the material. And they are significantly harder than steel, which you can identify by their toughness and wear resistance.

Below other recognition methods for your reference.

- Visual inspection: To look if there is a distinct gray color and metallic sheen, if yes, it is carbide.

- Manufacturer’s markings: Checking markings indicating the material used. Sometimes the manufacturers will mark something on the insert body.

- Magnet test: Carbide inserts are non-magnetic, unlike steel or other metals. If it can be attached to a magnet, it is not a real carbide blade.

Tungsten carbide inserts offer significant advantages in precision cutting and machining across diverse industries. Their durability and resilience make them indispensable tools for achieving high-quality results in various manufacturing processes.

Then would you like more detailed information on any specific application or aspect of cnc inserts? Please contact us freely!