How To Obtain Top Quality Cold Forming Dies From China?

Fastener cold forming dies are an important component of industrial products, therefore, the quality requirements for cold forming dies are very strict. The improvement of the development of the mold industry itself has led to the improvement of the technology of fastener molds. As China’s economy enters a stable period and the industrial structure is gradually optimized, the quality requirements for industrial products are becoming higher and higher, and the same is true for fastener molds.

It is expected that in the future, China’s fastener cold forming dies will develop towards the high-end direction. In recent years, with the rapid development of China’s mold industry, the standardization, specialization, and commercialization of mold parts have reached a high level and made significant progress. Most industrialized countries attach great importance to the development of fasteners, and of course, they cannot do without standardized fastener molds.

ZHUZHOU UKO PRECISION CARBIDE CO.,LTD-We are specialized producer of tools for cold heading and thread rolling machines.

Focusing on Forming Die Set as below:

●Tungsten Carbide Dies for Screws

●Cutting Dies, Shearing Dies

●Bolt Heading Dies

●Punch Dies

●Hex, Flange Segmented Forming Dies

●Trimming Dies

●Flat Thread Rolling Dies

Why choose us?

1.Extensive experience in the production of fasteners;

2.Use of high quality tool steels and tungsten carbide with strict input control of raw materials;

3.Equipping with modern and high-tech EDM machines, vacuum furnaces, CNC metal-working machines;

4.Application of wear-resistant coatings: titanium carbides and nitrides and others;

We sell not only products, but also technic and service. If you have new request for Forming Die Set , please contact with us,UKO can be your reliability partner. We devote ourselves to creating quality products at affordable prices,with an unwavering passion to exceed customer expectations at every turn.

Production Introduction:

Punch Dies

The product specifications cover major standards such as ANSI, JIS, DIN, GB, ISO, etc. The punching needle types include: cross, meter shaped, straight shaped, plum blossom, hexagonal, square hole, etc. It can also be specially developed and manufactured according to customer requirements. The factory has advanced production equipment and technology, uses high-quality steel raw materials, and has passed the ISO9001:2008 quality management system certification to ensure product quality.

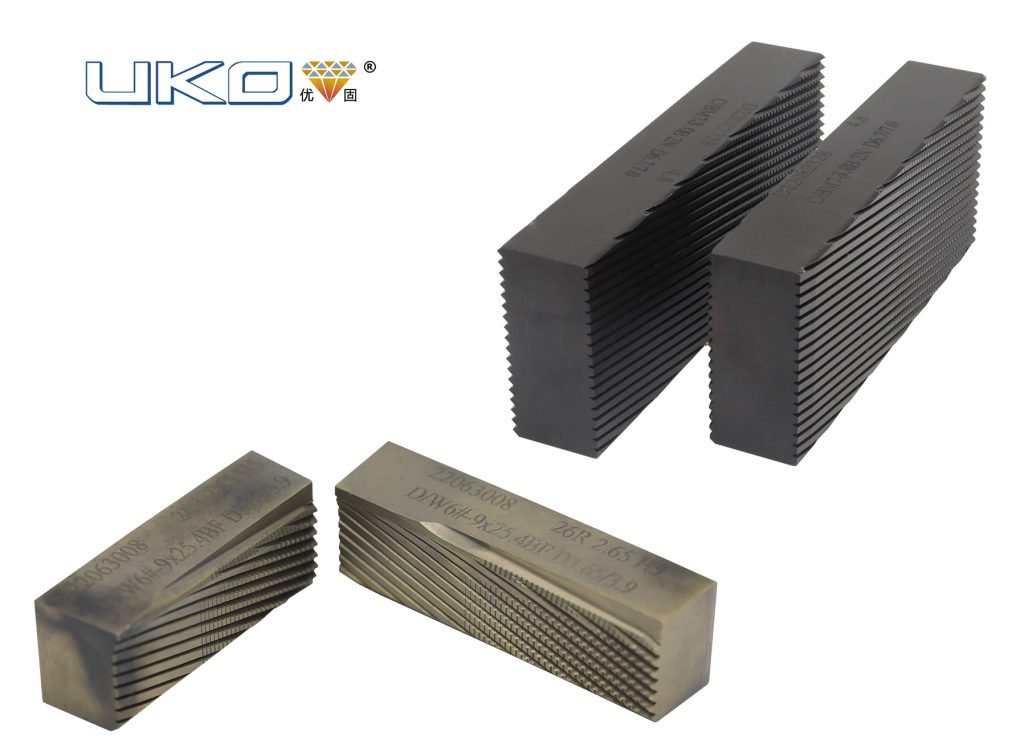

Flat thread rolling die

It is used for external processing thread. Threads are made by rolling, grinding, or milling. Flat thread rolling dies with precision class 1, 2, or 3 can be manufactured and processed according to the specified precision requirements. Through a series of heat treatments, the hardness of the dies can reach HRC63. Therefore, it has very stable performance and high efficiency.

●Material: Cr12MoV, DC53, D55, H5, H9 and high speed tool steel

●Thread forms: ISO, BSP, UNF, UNC, BSW, BA, BSC, and so on

●Type: Single-face Dies and Duplex face Dies

●Applications/usage: used for making self-tapping screws, wood screws, Drywall screws, machine screws, and so on.

UKO have been committed to becoming an excellent provider of screw forming molds and solutions. By improving the management system, continuously improving production technology, continuously developing and innovating, actively responding to customer needs, and striving to provide customers with high-quality and reasonably priced products and services, our work has been recognized and supported by a large number of customers.