Data: Not the Cyborg from Star Trek, Air Data

This world is a constant gathering of data anymore. Every item that connects to the internet moves data, collects data, and shares data. The problem is often, what data is truly needed and what we can do with it. When it comes to business analytics and data there are many types. The same can be said for compressed air.

When looking at the data your compressed air system is collecting and what data matters, it is good to understand the types of data we could be dealing with and what could be detrimental. That’s right, too much data can be a bad thing. Or data that hasn’t been refined and is coming in not in the correct format can also be crippling to analysis. The first is too much data and be considered “Vampire” Data, there is so much there that it just simply sucks all the energy out of your analysis and can lead to paralysis through analysis. The second would be considered “Dirty” data. This data causes lots of additional work to clean up and process. Rather than just importing, running with it, and being able to take off, it generates many of its own work levels and may even have erroneous readings in it throughout that can also cause issues. So how can we identify these within our compressed air system?

What could vampire data in a compressed air system look like? Well, multiple Flowmeters collecting data on the same branch line without any offshoots would be the first. If you have a loop-style main, there would be no need to measure the flow coming out of your dry storage and going into the header loop, then measure the header flow again before the first drop. A second instance would be taking measurements in a high quantity during system downtimes, this could be the off-hours period, and there isn’t a need to monitor every second if nothing is running. Now, monitoring overnight is needed, this helps to monitor leaks or other phantom draws of air while equipment is not running. It doesn’t need to be monitored every second of the off hours though. So try to keep this nuisance to a minimum and if you aren’t sure where you should install Digital Flowmeters, contact an Application Engineer to discuss.

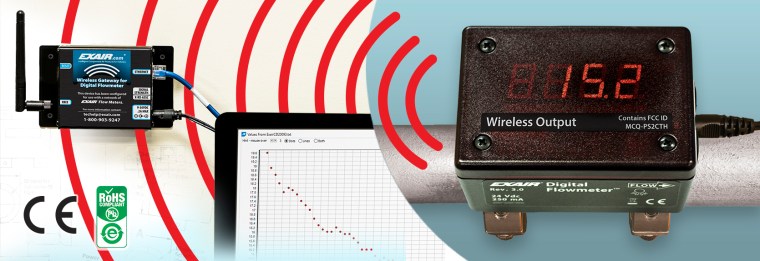

The latter, dirty data, is sometimes harder to take care of. This can be caused by different sources all feeding data into separate files or even importing routines from equipment not being refined. This can also be due to operator error when collecting manual data points or not following standard operating procedures. One way to reduce the number of items to import data from is by utilizing equipment like Digital Flowmeters with Wireless Capabilities and also pressure-sensing flow meters. These all help to reduce the number of items or routines in a compressed air system data collection. Again, if you aren’t sure how to clean up data, or how to process the data coming out of our EXAIR Logger software that is included with the Wireless Capability Digital Flow meter, that’s what we are here to help with.

No matter what, data in a compressed air system is important and helps to create system profiles, deduce failed equipment, refine processes, and most of all give you the ability to calculate ROI after installing engineered solutions. If you want to discuss how to do this, reach out to an Application Engineer today!

Brian Farno

Application Engineer

BrianFarno@EXAIR.com

@EXAIR_BF