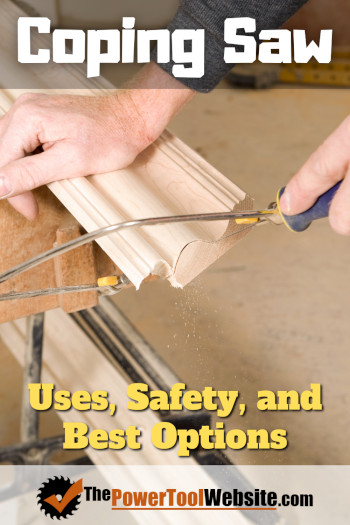

Coping Saw: Uses, Safety and Best Options – Read Before You Buy

Definition of a coping saw

You may have seen the carpenter using a coping saw to clean out dovetails or for creating matching baseboards. You may have also seen signboard makers using this hand tool to shape closed letters.

Now look around and identify what else in your home may have used a coping saw to finish a project. Molding and furniture items are the next big suspects and rightly so. Many objects are required to be made with this tactful tool.

It was during a long holiday, I came to realize the importance of this small hand tool. I wanted to cut a design into an acrylic sheet for my lampshade project. The options that I had included assigning the work to a CNC service provider or DIY with a coping saw.

I decided to keep the first option for another day while choosing to make my hand dirty working with a coping saw. I must tell you, this small hand tool has a special place when it comes to how much it achieves out of its skeleton frame.

But there are certain things to keep in mind while working with it. To use it safely, you should use a clamp to secure your workpiece safely. Choose the blade carefully. They are normally 6.75 inches long and have 10 to 20 teeth per inch. If you are going to work with jewelry pieces or small metal surfaces, a fret saw could be a good option.

What is a coping saw?

A coping saw is a hand tool used for cutting the fine and intricate design on a wood, plastic, MDF, or metal surface. It is similar to a jigsaw or scroll saw. It is a small, manual, and hand-operated tool.

You can use a coping saw to cut intricate designs, shapes, and curves. The coping saw is often referred to when we have a coping joint work on hand. It is a kind of joint in which one piece of the molding corner is cut to fit into the contours of its corresponding piece.

What makes a coping saw so very useful is the flexibility with which the blade can be used. For example, it can perform interior cuts and designs in the interior of a surface without cutting from the perimeter of the material.

This is possible because the blade can be removed from its frame, inserted into a drilled hole on the surface, and refitted into the frame to continue the cutting job, starting from the drilled hole onwards. In this manner, a design can be made deep into the surface but not cutting through the perimeter.

Use cases

A coping saw is frequently used for cutting appropriate designs for joining one surface to another. This small hand tool is capable of delivering those fine and tight cuts that go into creating inside joints with a superior professional finish.

How you can use a coping saw safely?

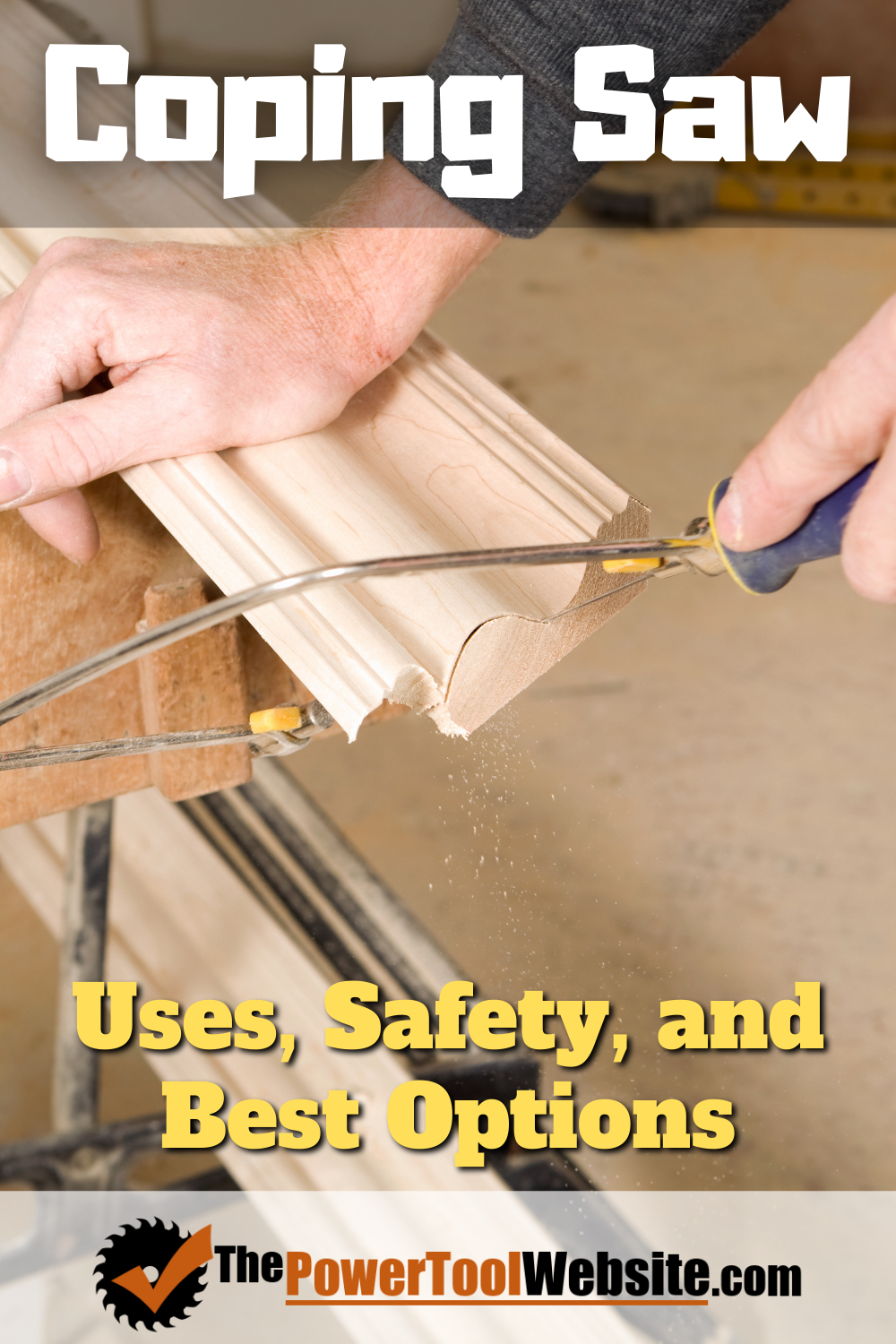

A coping saw is a useful hand tool that allows you to create intricate fine cuts and designs into a surface. Since a coping saw uses a fine blade made of hardened steel which is capable of rendering a cut on your hands or other body parts, you should use this tool only with caution.

Wear PPE

When you work with a coping saw, you work very closely with the material. As it involves cutting into a surface, the working of coping saw throws up shards that can get into your eyes. So, you must wear safety glasses to prevent shards and dust from entering your eyes.

Use a protective case for your tool

The blade of the coping saw is sharp and when it is fixed into its frame it is tight and tense. The entire tool works as a single unit. If it falls on your body or you accidentally hit it, you can injure yourself. The best way to deal with it when you are not using it is to keep it in its protective sheath or holster. This will ensure the safety of both you and your coping saw.

Maintain safe distance

The coping saw has a blade with sharp teeth. When you are cutting a surface, you should keep your hands and fingers away from its path. You should also keep unnecessary things away from the area where you are working. This is necessary to make sure the coping saw does not cut unintended things.

Keep your machine in good condition

The blades of a coping saw are economically priced. If the blades you are using have become dull, or have bent, or have missing teeth, you should replace them. When using make sure, the blade is not loose on its frame.

Oil the saw

After each use, you should oil the teeth of the blade. For this, you should put on a pair of industrial hand gloves and apply the lubricant on the saw’s teeth. Follow the instructions on how to apply the lubricants.

How to choose a good quality coping saw?

For the kind of applications for which coping saws are used, they must be lightweight. Since they are already minimal and skinny in their design, not much improvement is expected either. The only thing we can expect is the high quality of material used for making the frame, handle, spigot, and blade.

The saws are coming in many different options and the quality of the material is the defining feature there. Some blades are durable and whose teeth do not become dull easily. The blades are defined by the number of teeth per inch and most standard blades have 14 to 16 teeth per inch. Among the best brands and models of coping saws include Olson SF63510, Bahco 301, Irwin ProTouch, and Stanley Fatmax.

Final thoughts

The coping saw is an extremely useful hand tool for professionals of many crafts and professions. It can create an interior cut and is capable of making intricate and fine designs.

But you need to know this simple-looking hand tool a bit better to be able to use it to your maximum advantage. You also need to adhere to safety guidelines

Related question

What is the benefit of a coping saw?

The availability of blades to cut wood, plastic, and even ceramic tile also make it an indispensable handyman’s tool. In the woodshop, a coping saw also excels at cutting curved parts for furniture and is especially useful for making interior cuts.